Modern import engines rely on precise fuel delivery. Tiny injector nozzles meter fuel in exact amounts and patterns, so the mixture burns cleanly and the engine responds the moment you press the pedal. Over time, fuel deposits and varnish narrow those passages. Spray turns from a fine cone into uneven droplets, and performance fades.

Proper injector cleaning brings the pattern back, along with the power, smoothness, and economy you remember.

Why Injectors Get Dirty in the First Place

Gasoline leaves behind microscopic residue each time the engine shuts off. Heat soak bakes that residue on the injector tip. Short trips make the buildup worse because the engine never spends long at full operating temperature. Low tank levels can stir up sediment, and extended storage lets varnish form. Even high-quality fuel allows some deposits over thousands of miles. None of this means something is broken, but it does mean the spray pattern has drifted from ideal.

Port Injection vs. Direct Injection

Port-injected engines spray fuel on the back of the intake valve. That helps keep the valve cleaner, but the injector tip still sees heat and can develop deposits. Direct injection places the injector in the combustion chamber at much higher pressure. The tips live in a hotter, harsher environment, so fine carbon can build faster. On DI engines, you may also see carbon buildup on intake valves because fuel no longer washes them. That is a separate service, but both issues reduce airflow and atomization, and they often show up together.

What Dirty Injectors Feel Like From the Driver Seat

The first signs are subtle. Idle feels a bit rougher on cold mornings. Low speed throttle takes a moment to wake up. Fuel economy slips a mile or two per gallon. Under load, the engine can ping lightly or feel flat in the midrange. In some cases, you might see a misfire code on one cylinder that comes and goes. Those symptoms often trace back to uneven flow or a distorted spray pattern.

How Professional Injector Cleaning Works

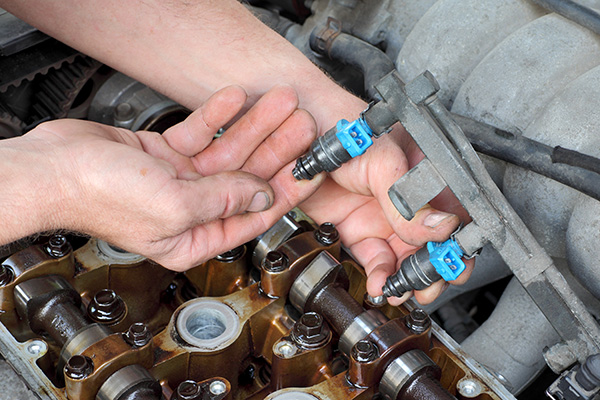

There are two main approaches. On-car cleaning runs a concentrated cleaning solution through the rail at controlled pressure while the engine runs. This dissolves deposits on the tips and restores the spray pattern without dismantling the system. For stubborn cases or when flow varies widely cylinder to cylinder, bench cleaning is the answer. Injectors are removed, flow tested, and ultrasonically cleaned. Screens and seals are replaced, and each injector is tested again for matched flow before reinstallation. The method depends on the engine design, mileage, and how severe the symptoms are.

Why Results Are Immediate and Measurable

Engines are calibrated for a specific atomization. When droplets are too large, the flame front slows and some fuel burns late, which wastes energy and heats the catalytic converter. Restored atomization gives a faster, more complete burn. You feel that as a steadier idle and stronger midrange pull. Fuel trims on a scan tool return toward zero as the computer no longer compensates for lean or rich cylinders. On turbo engines, boost comes on cleaner because the mixture is consistent across cylinders.

What We Check Before and After Cleaning

Injector cleaning should not be guesswork. We start with fuel pressure tests, scan for codes, and review fuel trims and misfire counters. If trims point to a vacuum leak or a weak pump, those come first. After cleaning, we verify trims at idle and cruise, confirm smooth cold starts, and road test under load. For direct-injection engines with rough idle or clear airflow symptoms, we may recommend intake-valve walnut blasting to complement injector service. Pairing the two restores both atomization and airflow.

Benefits You Can Expect From a Correct Service

- Smoother idle and quicker throttle response

- Reduced hesitation on hills or highway merges

- More consistent fuel economy on your normal route

- Lower chance of misfire codes related to uneven fueling

Most drivers notice the change right away, particularly on engines with higher mileage or lots of short-trip use.

How to Keep Injectors Clean Between Services

Use quality fuel from busy stations and avoid running the tank to near empty, which stirs up sediment. If your driving is mostly short trips, schedule an occasional longer drive so the engine spends time fully hot. Replace the engine air filter on time; a restricted filter can skew fueling. Follow the oil specification for your engine, as some oils reduce deposits in direct-injection applications. If the vehicle sits for long periods, a storage-safe fuel treatment can slow varnish formation.

Injector Cleaning for Imports at Import Auto Specialists in San Diego, CA

If your import hesitates, idles roughly, or feels down on power, Import Auto Specialists can help. Our team tests fuel pressure and trims, performs on-car or bench injector cleaning as needed, and verifies results with data and a road test. We also address related issues like intake valve carbon on DI engines, so the improvement lasts.

Call or schedule service at our San Diego location today to restore the clean spray pattern, strong response, and dependable efficiency your car was built to deliver.